The current debate around climate change and the contribution of humans to this phenomenon will rage on unresolved for decades. There is a fundamental lack of agreement between those that agree and those that don't. The reason is quite simple. The issue centres on the difficulty in scientifically quantifying the amount by which human activity is causing a detrimental impact. Regardless of this, governments worldwide, not just in Australia, are spending billions of taxpayer dollars on schemes, many of which are highly questionable; to show that they are a part of the 'solution'. The question is whether this massive utilisation of scarce financial resources and its huge opportunity cost to the taxpayers is an equitable one.

The current debate around climate change and the contribution of humans to this phenomenon will rage on unresolved for decades. There is a fundamental lack of agreement between those that agree and those that don't. The reason is quite simple. The issue centres on the difficulty in scientifically quantifying the amount by which human activity is causing a detrimental impact. Regardless of this, governments worldwide, not just in Australia, are spending billions of taxpayer dollars on schemes, many of which are highly questionable; to show that they are a part of the 'solution'. The question is whether this massive utilisation of scarce financial resources and its huge opportunity cost to the taxpayers is an equitable one.

There is no point in trying to invent a square wheel when a round one exists! And yet many are still trying to experiment with all sorts of different models! This is the situation that exists in Australia. The methods of achieving airtightness and weather tightness are widely known in Europe, USA, Canada and other developed parts of the world. The system for achieving this is proven.

There is no point in trying to invent a square wheel when a round one exists! And yet many are still trying to experiment with all sorts of different models! This is the situation that exists in Australia. The methods of achieving airtightness and weather tightness are widely known in Europe, USA, Canada and other developed parts of the world. The system for achieving this is proven.

Modus operandi

There are two very important tools in the quest for airtightness. The vapour permeable and semi permeable membranes and the highly specialised tapes used in sealing to the structure. Diffusion of vapour is extremely important because of the tightness of the structure and the membranes and tapes used must be vapour permeable at differing levels to this activity and having due regard for the build location climate. It is vitally important to ensure the diffusion of vapour is expelled from the frame cavity through differing conditions across the year.

The Structure Wrap – The external face of the structure's frame (assume it is timber for the purposes of this discussion) needs to be wrapped with a permeable monolithic weather resistive barrier. It may typically have an Sd value of 0.05 and must not retard the diffusion of vapour through to the outside. (Sd is the dimension for the diffusion resistance of a component to water vapour - described as air layer thickness for this application).

The membrane must be sealed to the base, for example the slab, so that it forms an airtight weather tight seal. This seal must be carried through to all openings through the membrane, e.g. perimeters of windows and doors, and penetrations. A high quality water-resistive barrier (WRB) that will do a superb job of protecting the structure, while helping as a first line of defence in achieving the airtight construction we are seeking, at the same time allowing any moisture in the wall cavities to escape. A monolithic WRB will move moisture through at a molecular level and at a faster rate than the traditional 'Sisalation' micropore wall wrap commonly use. Additionally there is a high probability these pores will get blocked during the construction process and cause a failure of even this limited function. The result is damage to the frame. This sisalation should not be used to wrap a frame, even though our code allows it!

The internal face of the structure should be wrapped as a minimum in a semi permeable diffusion vapour control membrane and should possess different properties to the external WRB. It may have a Sd value of 5 upwards (in other words a Fixed Sd membrane) and should allow easy passage for vapour diffusion through to the inside, from the frame cavity. Ideally, it may also be restrictive in allowing it back out into the structure cavity where it could do damage.

An advance on the fixed Sd membrane is the Diffusion Vapour Variable control membrane (so called 'Intelligent' membrane). The VVC membrane is relatively vapour closed when air is relatively dry but becomes increasing vapour open when exposed to humid air. (Open in humid conditions, closed in Dry conditions). During winter heating, the water vapour on the structure's internal (humid) side wants to move through the VVC membrane material to the air on the dry side. The diffusion vapour drive is to the outside. A VVC does not open up in summer or close down in winter as some sales personnel and suppliers will tell you and they are not always clear about how, when and why the materials change permeability in service. However what happens when there is a rapidly induced change?

A Variable Vapour Control Membrane is not really 'intelligent' as claimed, Why? Because it doesn't sense moisture. Nor is it capable of detecting which side the moisture is on. As it get progressively wet with moisture from its environment, it undergoes a physical change opening up at the molecular level to allow a greater number of water molecules migrate through at a faster rate. The problem with allowing a state of open vapour diffusion through to the frame cavity at the wrong time, (when it is winter conditions on the outside and it should be in retarding mode) is that it can result in damaging excess moisture condensing on the frame.

For example, set in winter, an 'induced' change may result from a classroom of 25 energised children that suddenly arrives, with the ability to generate a large amount of humidity in a very short period of time! Or a newly plastered interior or a newly screeded heated flooring system. These activities create potential to generate massive amounts of humidity into the air. The so called 'intelligent' VVCM opens up and allows vapour diffusion into the frame cavity to its single Sd value.

Due to the winter temperature in the frame cavity, this results in condensation within the frame. The same may result in public buildings with transient populations or intense activity areas or pool areas or flat roofs which frequently have no ventilated rear cavity area. If this is happens often enough, the end result is structural damage. Research by the Aachen Institute of Building Damage Research and Applied building Physics found that because of their inability to sense which side the moisture is on, Variable Vapour Control membranes opened up with 'induced' changes, resulting is structural damage.

What's the Ideal Vapour Diffusible Membrane -

Would possess the ability to sense moisture and which side it is on and thereby react earlier. Preferably it will possess differing Sd levels – one for the diffusion seeking to enter from the frame cavity and a different more retarding Sd for diffusion seeking to leave the internal area into the frame cavity, which we know is something to be actively retarded.

Retarding diffusion to the outside limits the concentration of vapour in the frame cavity thereby facilitating it to dry out rather than cause damage. In the event of an induced vapour drive change, the different Sd on the inside will not allow diffusion to occur the same rate as if it was seeking to enter from the frame cavity. As we have seen, this could have damaging consequences for the structure if it occurred over a period of time because of the accumulation of moisture. So what we are seeking is 'one directional transport' of vapour diffusion with a 2 dimensional Sd value membrane. Sounds like science fiction.

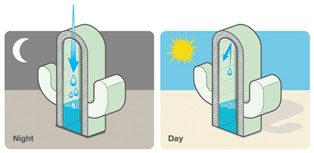

SIGA looked to the humble Cactus to understand how this could occur. The Catus allows moisture in through the night but not out during the blazing hot desert day. In effect one directional moisture transport!

SIGA looked to the humble Cactus to understand how this could occur. The Catus allows moisture in through the night but not out during the blazing hot desert day. In effect one directional moisture transport!

This formed the basis for the multi-year development of the world's first Hygrobrid® Technology Vapour Control Membrane. It is called Majrex®

Testing conducted by the TUD proved that Majrex® with Hygrobrid® technology significantly reduces moisture development in the structure compared with conventional variable vapour control membranes, and the diffusion of any moisture that is in the structure to the outside is faster. Hygrobrid®allows Majrex to react faster but Majrex® also has 2 dimensional Sd construction. The inside skin possesses a more retarding Sd value when compared to the outside skin of the membrane which is more vapour diffusion open.

Testing conducted by the TUD proved that Majrex® with Hygrobrid® technology significantly reduces moisture development in the structure compared with conventional variable vapour control membranes, and the diffusion of any moisture that is in the structure to the outside is faster. Hygrobrid®allows Majrex to react faster but Majrex® also has 2 dimensional Sd construction. The inside skin possesses a more retarding Sd value when compared to the outside skin of the membrane which is more vapour diffusion open.

Majrex® scored another world first. It is the only Vapour Control membrane to be awarded component certification by the Passive House Institute. This is the ultimate accolade for such a membrane, and one of the toughest to obtain.

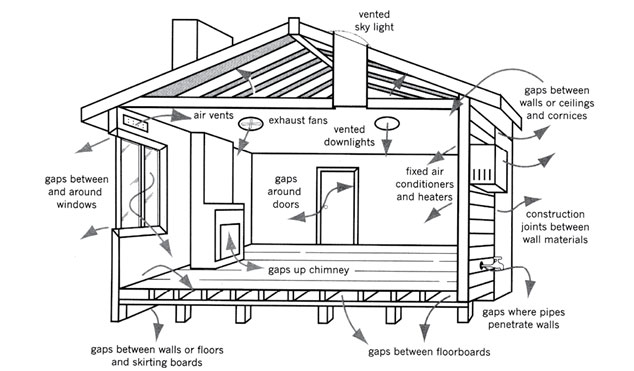

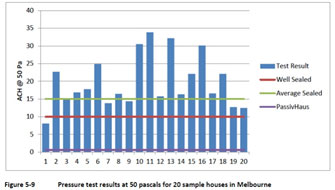

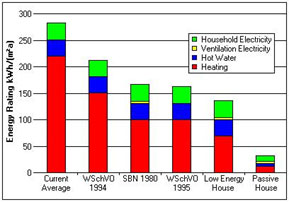

Suggesting that buildings must be allowed to 'breathe' is a throwback to the Victorian age. An energy-efficient home must be as airtight as possible. Current 6 star homes have an average 15ACH...a travesty for the owner and the environment. An Airtight (High Performance low energy) home will be up to 5 times more energy efficient than a standard leaky home according to the Franhofer Institute of Construction Physics. A handful of basic components working in synergy are needed to make this happen.

Suggesting that buildings must be allowed to 'breathe' is a throwback to the Victorian age. An energy-efficient home must be as airtight as possible. Current 6 star homes have an average 15ACH...a travesty for the owner and the environment. An Airtight (High Performance low energy) home will be up to 5 times more energy efficient than a standard leaky home according to the Franhofer Institute of Construction Physics. A handful of basic components working in synergy are needed to make this happen.

A high quality airtight building envelope system like SIGA membranes and tapes to wrap the structure, high quality double glazing made from a material that mitigates thermal bridging such as uPVC, mitigating structural thermal bridging and an Energy Recovery System (ERV) or HRV system that will perform the dual tasks of ventilation and energy recovery. More humid areas may require moisture management on board.

Mechanical ventilation is important because the tighter a structure gets past 5ACH, the requirement for mechanical ventilation becomes a necessity to ensure a healthy internal air quality. Healthy internal environments maintaining around 50% humidity is an ideal requirement for a human, and deadly for mould, mildew and other bugs and viruses that cause illness.

The principles of High Performance (low energy) and Passive House champion Airtightness. Once the building envelope has been wrapped and or prior to handover, a blower door test is conducted to determine where there are leakage areas in the building fabric. Using a thermography camera, leakage in reference colours is identified easily. Essentially, using depressurisation and pressurisation runs of the structure, readings measured in ACH air changes per hour are taken and averaged. So a blower door test is critical to final evaluation of a build. The airtightness, energy recovery and minimised thermal bridging results in a build that maintains a very stable consistent temperature throughout the home with greatly reduced requirements for heating-cooling loads.

Architects and Building Designers are now in the driving seat to effect real and meaningful change to the energy efficiency of buildings in Australia. Those interested in specifying Airtightness for Commercial or Residential applications only need to specify "The SIGA Airtightness System". The builder contacts SIGA and we will assist and train the builder to implement the system for ultimate effectiveness.

Edward Mazria is correct in his statement that you control the global thermostat.

Please click on the SIGA House image below to review the system products. Further detail is contained in the 'Product' page of this website. You may also call our SIGA Experts who will be pleased to assist and recommend the appropriate combinations for you.

www.zeroemissionsbuildingproducts.com.au Tel: 8742 7995 Mob: 0468 459 659

Zero Emissions is the Official distributor and educator for SIGA products in Australia.